Accelerated Cured Concrete Test / Accelerated Cube Test / ACT of Concrete

Preamble

Traditionally, the quality of concrete is calculated based on its compressive strength after 28 days. This procedure requires multiple test specimens of 150 mm size concrete cubes to be cast and cured in water for 28 days. The concrete cubes are taken out and subjected to compressive strength testing in a concrete cube testing machine (CTM); some after 7 days and some more after 28 days.

The test result will determine the compressive strength and, thereby, the grade of the concrete. The indicative strength on the 7th day of testing shall be greater than 60% of the target strength on the 28th day.

If, after 28 days, the quality of the concrete is found unacceptable, the concrete would have hardened or even got buried by subsequent construction. The replacement or rehabilitation of this concrete becomes difficult and often impractical.

On the other hand, if the concrete has excessive strength, it would be too late to prevent wasteful expenditure in terms of using excessive cement.

Therefore, standard 28-day testing is too late and not feasible in terms of quality control, construction cost control or taking timely corrective measures for any defects.

What is the Accelerated Curing of Concrete?

Accelerated curing is the method used to find out the compressive strength of concrete in 28 Hrs which traditionally would have been achieved in 28 days. This is achieved by raising the temperature of the curing water to speed up the hydration process of cement, thereby achieving high early compression strength.

The test is carried out after 28hrs of accelerated curing. The result is interpreted by using an appropriate correlation curve obtained by testing normally cured and accelerated cured concrete specimens of the mix proportion and materials to be used at the site.

This method is applicable for most of the test specimens prepared at construction sites to provide results of low variability.

Why Accelerated Curing is Required?

An accelerated curing method is required to achieve the early compressive strength of the concrete structure. This helps to provide faster project delivery; control cost by using optimum cement content, and to assist in taking rectification actions for bad work while the concrete is still accessible and sufficiently green to make its removal practical, that is, within about 24 hours after casting.

In actual site conditions, accelerated curing reduces the cost by reducing formwork removal time. Thereby it makes the structure functional at an early stage.

What are the Applicable Codes and Standards?

IS 9013 lays down the method for making, curing and testing in compression specimens of concrete stored under conditions intended to accelerate the development of strength.

What are the Accelerated Curing Methods?

There are two accelerated methods in this standard for quality-control purposes or for predicting the normal strength of concrete at later stages. They are the warm-water method and the boiling-water method. The most common method is the boiling-water method for accelerated curing.

Apparatus for an accelerated cured concrete test?

The following apparatus is required;

- Slump cone

- Cube moulds conforming to IS 516

- Mould cover plates

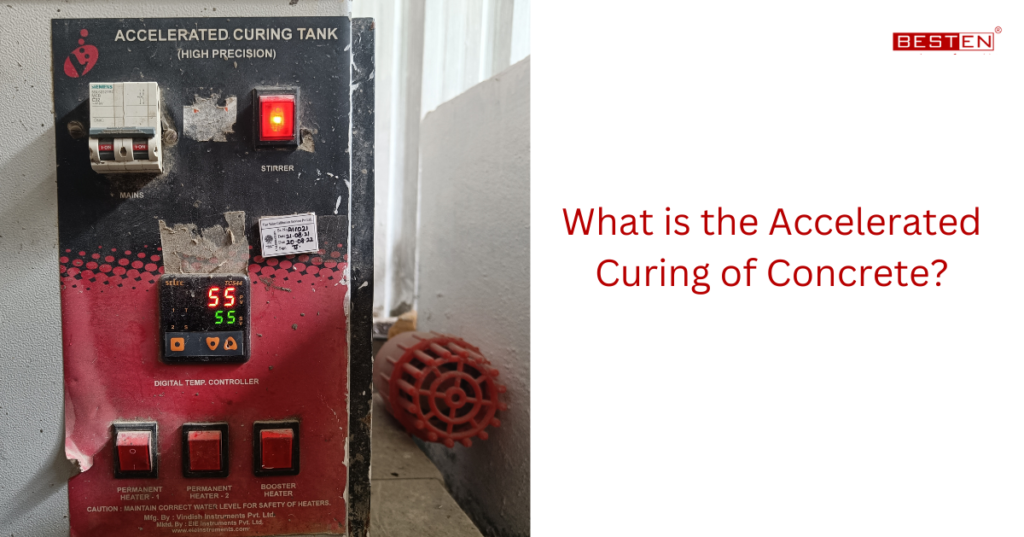

- Hot water tank

- Cooling water tank

- Concrete cube testing machine (CTM)

What is Accelerated Curing by Boiling-Water Method?

Prepare the test specimen in standard moulds and leave it undisturbed for 23 Hrs ± 15 Mins in moist air with at least 90% relative humidity and at a temperature of 27 ± 2 Deg. C from the time of addition of water to the ingredients. Cover each specimen immediately after moulding with a steel plate thinly coated with mould oil.

Lower the test specimen with moulds into a boiling water tank. Maintain the water in the tank at 100 Deg.C. The temperature of water shall not drop more than 3 Deg. C immediately after immersing the specimen. The temperature shall return to boiling within 15 minutes. The specimen with their moulds shall remain fully immersed in boiling water for a period of 3.50 Hrs ± 5 Mins.

After the curing period, remove the specimen with its moulds from the boiling water. Cool them by immersing them in a cooling water tank at a temperature of 27 ± 2 Deg. C for 2 Hrs.

After the cooling period, remove the specimen with its moulds from the cooling water tank. Demould the specimens. Finally, test the cubes for their accelerated compressive strength (Ra) in accordance with IS 516.

What is Accelerated Curing by Warm-Water Method?

Prepare the test specimen in standard moulds. Leave it undisturbed for at least 1Hr at a temperature of 27 ± 2 Deg.C from the time of addition of water to the ingredients prior to immersion in the curing tank. Cover each specimen immediately after moulding with a steel plate thinly coated with mould oil.

The next step is to lower the test specimen with their moulds gently into a curing tank. Maintain the water at 55 ± 2 Deg.C for a period of not less than 19 Hrs 20 Mins. The time between the addition of water to the ingredients and immersion of the test specimen with their moulds in the curing tank shall be at least 1.50 Hrs but shall not exceed 3.50 Hrs.

After the curing period, remove the specimen with its moulds from the water and de-mould it. Subsequently, cool the specimen by immersing them in a cooling water tank. The water has a temperature of 27 ± 2 Deg.C before the completion of 20 hours 10 minutes from the start of immersion in the curing tank. The specimen shall remain in the cooling tank for a period of not less than 1 Hr.

After the cooling period, remove the cubes from the cooling tank. And then tested for their accelerated compressive strength (Ra) in accordance with IS 516.

The calculation to Predict 28-Day Compressive Strength (R28) using Accelerated Compressive Strength (Ra)

Predicted 28 days compressive strength R28 = 8.09 + 1.64 Ra. Wherein Ra is accelerated compressive strength, and R28 is predicted compressive strength at 28 days.