What are Air Handling Units?

Air handling units or air handlers supply and circulate air in a building. Mechanical consultants recommend Air handling units, or AHUs, to extract air and contaminants and form a part of the HVAC system of the building.

Benefits of AHU

AHU systems are a critical part of the HVAC system in any facility. These systems help in environmental control and the well-being of the workforce. These well-engineered systems are crucial in providing clean air inside the building. Some other benefits are:

- Contaminant Mitigation: Industrial processes generate diverse airborne hazards, from dust and fumes to gases and volatile organic compounds (VOCs). Industrial AHUs capture and filter these contaminants, safeguarding worker health and ensuring compliance with environmental regulations.

- Climate Control: Maintaining optimal temperature and humidity is crucial for worker comfort and equipment performance. Industrial AHUs achieve this through advanced heating and cooling coils, preventing heat stress, equipment damage, and even product inconsistencies.

- Odour Control: Unpleasant and potentially harmful industrial odours can significantly impact work quality and employee morale. Industrial AHUs neutralise and remove these odours, fostering a hygienic and conducive work environment.

- Ventilation Optimisation: Continuous replacement of contaminated air with fresh air is vital for maintaining acceptable air quality. Industrial AHUs achieve this through sophisticated ventilation strategies, ensuring a healthy and productive atmosphere for the workforce.

Features of Industrial AHU:

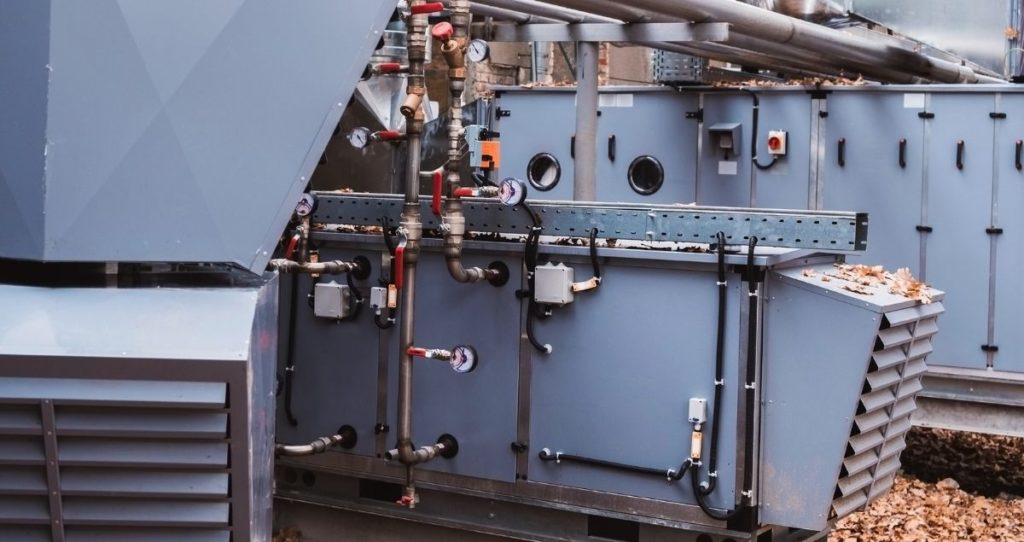

Their powerful fans propel massive air volumes through strategically designed ductwork. It cools or heats and circulates air throughout the room via ductwork. AHU contains air filters, blowers, and heating and cooling components. The features of AHU are:

- Structural Integrity: Heavy-duty construction withstands demanding operating conditions and harsh environments.

- High-Performance Fans: Powerful airflow ensures efficient contaminant removal and air circulation.

- Multi-Stage Filtration: Filters ranging from pre-filters to HEPA and activated carbon effectively capture dust, particles, and harmful gases.

- Climate Control: Heating and cooling coils maintain optimal temperature and humidity levels.

- Intelligent Control Systems: Advanced controls optimise operation, maximise energy efficiency, and ensure system performance.

Types of AHU

AHUs are of two types, depending on the location of installation. The two types of AHUs are:

- Floor-mounted AHUs and

- Ceiling suspended AHUs

Factors that Mechanical consultants consider during selection

The mechanical consultants need a multifaceted approach to choose the AHU. The factors that they consider are:

- Airflow Requirements: The air volume guides the MEP consultants to choose the correct size and capacity.

- Contaminant Profile: Contaminants and their concentrations help decide on the filtration and equipment.

- Environmental Conditions: The mechanical consultants consider temperature, humidity, and special considerations like the explosion-proof needs of the project.

- Energy Efficiency: Selecting energy-efficient AHUs minimises operational costs and promotes environmental sustainability.

Advantages of a Well-Designed AHU:

A well-designed AHU has multiple benefits. Some of the benefits for mechanical consultants to select AHU are as follows:

- Better health and safety of the workforce

- Better production

- Improved production and consistency

- Optimised operational costs

- Sustainable operations

- Compliance.

Conclusion:

Industrial air handling units are an investment in operational safety, productivity and sustainability.