What is Total Design?

Working concurrently on multiple disciplines in a project is “Total Design”. This is especially relevant in industrial infrastructure projects, where an integrated approach “total design” helps capture the entire requirements of a project in the initial stage itself.

Sir Ove Arup’s “Total Design” philosophy of collaboration all professions from the very outset of a project is as relevant today as it was then. He believed that bringing all disciplines in a project together would result in the best possible outcome.

Any industrial infrastructure project, be it greenfield or brownfield, would have a faster and more productive design process if the “Total Design” philosophy is followed.

In an industrial project, typically a core team with representatives from the client’s end and specialists like design consultants, process consultants, etc. The process starts with a kick-off meeting and creating a design charrette. As the subject experts add in their years of experience in their domain, there are minimal surprises during the implementation. Total design helps to make well-informed decisions as all the stakeholders are a part of the charrette.

In a fast track industrial project, total design helps achieve the project timelines while staying within the approved budget. The involvement of the stakeholders in the initial brainstorming sessions ensures that everyone is on the same page.

What are the benefits of total design in industrial infrastructure projects?

- It encourages teamwork and collaboration between disciplines. As a result, total Design eliminates the various difficulties that crop up in the “silo” design style.

- The design process is faster because the team members from various disciplines participate in brainstorming sessions. They anticipate the issues that can come up and look for solutions. This helps in reducing change requests during construction.

- Integration of all the disciplines in a project gives a more optimized outcome.

- It helps to improve predictability during construction, operations, and maintenance.

- Total Design helps provide a cost-optimized solution. There are multiple brainstorming sessions in which expectations during activities like constructability, operations, and maintenance are considered.

- The multi-faceted team helps bring the members’ experience to anticipate bottlenecks and solutions during the design stage. As a result, the fixes are usually thought over and then incorporated into the design.

- The consultants following the “Total Design” philosophy are usually faster and get better results than those who follow the “Silo” style.

- Milestones and Delivery schedules can be planned well in advance.

Why is total design better than the conventional method?

This process scores better in comparison to the conventional method of designing in the following ways:

- The total design is an inclusive process involving the stakeholders from the beginning. However, in a conventional, the designers from other disciplines are involved only when required.

- In Total design, there is a lot of time invested early in the project, whereas the time invested is little in the conventional method.

- The total design method of the decision-making process involves a group of people. In a conventional design, the decision likes in the hands of very few people.

- The total design is an iterative process. Whereas, in conventional design, it changes as the design progresses.

- The cost and space are optimized to the maximum in total design, as various people are involved. The inputs and the agreed iteration in the design give a maximized result.

- The delivery period of various components in an industrial project varies. Some are long lead time delivery items; some are off-the-shelf. These orders have to be linked to the construction schedule. Hence, this necessitates a properly planned order schedule linking it with the construction schedule.

What is the composition of the project team?

Team Composition: It is vital to have a well-selected core team. The client’s team consists of representatives from the following departments:

- Management

- Operations

- HR

- Safety, Health & Environment

- Finance

- Marketing

- Process consultant

- Liasoning consultant

Furthermore, the team from the design consultant’s end typically consists of representatives from the following:

- Architectural department

- Conceptualization department

- Civil department

- Structural department

- MEP department

- Plumbing & sanitation department

- Drafting department

- Quantity Surveying department

- Specification department

- Tendering department

Usually, the design consultant’s project coordinator is usually an architect or an engineer who has experience in similar industrial projects.

What is the role of an industrial design consultant in Total design?

An industrial design consultant’s multi-disciplinary team usually varies depending on the project and its requirements. The team needs to be headed by a level-headed, experienced person.

The role of a design consultant usually is as follows:

- Help the client create a project team.

- Prepare a communication protocol inside the design team.

- Be able to actively listen to what all the members have to say about the project.

- Documenting the requirements of the client and sign it off.

- Create a project goal w.r.t the facility, budget, and schedule.

- Prepare a preliminary cost estimate.

- Prepare a conceptual plan in line with the statutory regulations of the area.

- Provide the client with multiple options for the facility.

- Prepare a design deliverable schedule in line with the project timelines.

- Prepare drawings for statutory approval based on the selected conceptual plan.

- Ensure that the communication lines are open with the client and the design team.

- Attend design charrettes with the client.

- Participate in meetings with the client and client’s consultants.

- Attend meetings between client and vendor

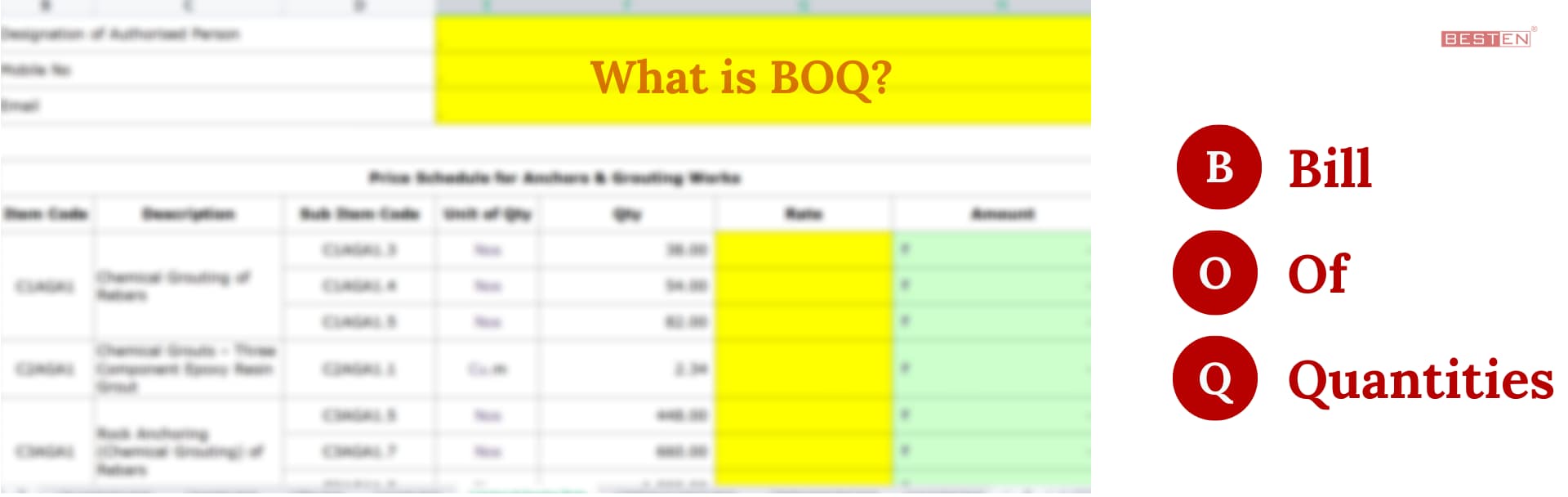

- Prepare tenders, BOQ.

- Assist the client in preparing a technical comparison between vendors.

“Perfection is achieved not when there is nothing more to add, but when there is nothing left to take away.” –Antoine de Saint-Exupery.

It is relevant in total design when the planning stage involves all the stakeholders, all disciplines, only relevant items are kept and the rest removed. As a result, the optimized design is achieved.

The total design is the need of the day as in any industrial project, timelines and project budgets are to be achieved. It is not long before Total Design becomes a global standard, especially for industrial infrastructure projects.