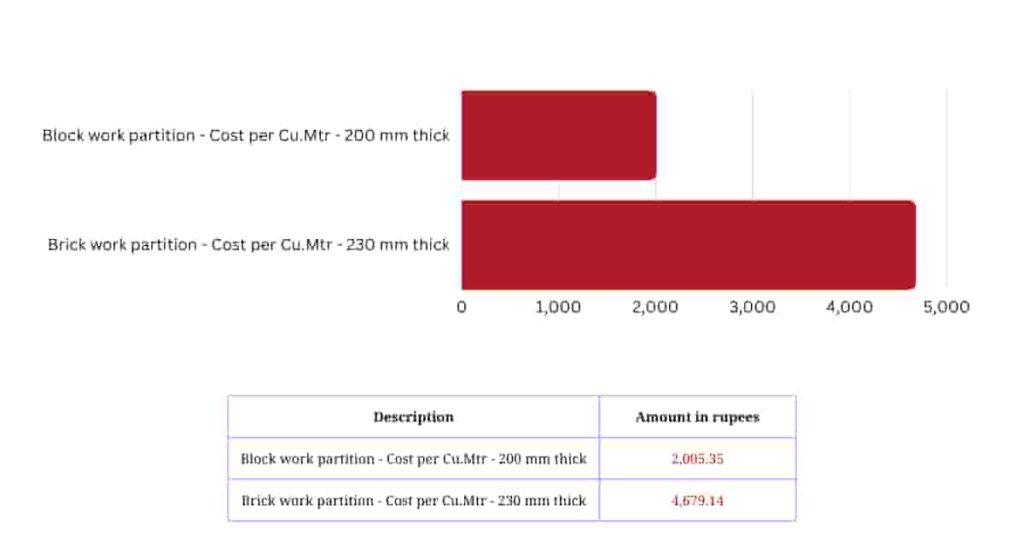

Both blockwork and brickwork are masonry components that civil engineering design consultants specify in industrial projects.

What is Blockwork?

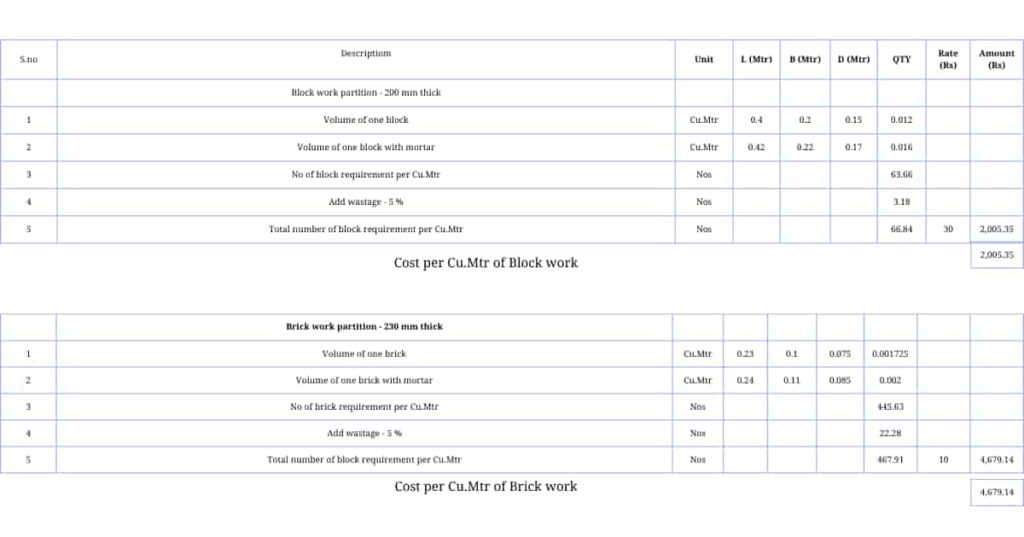

Blockwork is a masonry construction technique using large concrete or cement blocks. These blocks are larger than bricks. They may be hollow or solid. It is easy and faster to work with blocks when compared with brickwork. Civil engineering design consultants recommend blockwork due to its cost-effectiveness and ease of use.

Sizes: Blocks are formed in steel molds. Available sizes are as follows:

- 400 x 300 W x 200 H

- 400 x 250 W x 200 H

- 400 x 200 W x 200 H

- 400 x 150 W x 200 H

- 400 x 100 W x 200 H

Control Joints: Control joints are required in a concrete masonry wall to prevent cracking due to shrinkage of the concrete blocks, temperature expansion/contraction and differential settlement of foundations.

Block works are recommended as load-bearing walls, retaining walls, boundary walls,

What is Brickwork?

Brickworks is a masonry technique using bricks. Bricks may be more expensive than blocks due to the material used. They are an aesthetic, low-maintenance and long-wearing walling option. However, the quality of the brick also may vary depending on the raw materials used.

Sizes: Bricks are typically 230mm x 110mm x 76 mm high. The size may vary based on the manufacturer and based on the material.

Advantages of blockwork over brickwork in construction

- Blocks are bigger than bricks, so faster construction timelines

- Blocks are lighter than bricks

- Blocks reduce the total weight of the building

- Heatproof and soundproof blocks are also available

However, it is the consultants designing the civil works who take a call based on the availability, project requirements on the use of brick or block.