What is a fire pump and what is its role in the fire protection system?

A fire pump is one of the most important and integral part of any hydrant based fire protection system. The fire pumps are selected by fire safety consultants for industrial projects based on the regulations of the fire department. The fire pump provides water at the required pressure to the yard hydrant, hose reel system and sprinkler system. Generally, the pumps use electricity or diesel for operation. Fire pumps help in containing the fire, as they distribute water through the hydrant based fire fighting system.

What is a fire water tank?

A fire tank is a static water source such as an underground sump, ground supported water tank, overhead water tank or a water reservoir connected to the fire pump.

What are the codes and standards for fire pump size selection?

The fire risk management consultants use different design codes such as IS, NFPA, FM Global for selecting the size of the pumps for a particular project. The fire safety consultants for industrial projects apply codes and standards depending upon multiple factors. Some of the factors are a type of project, geographical area, local statutory requirements, client preferences, risk management philosophies etc. It is possible in some projects that different design codes are collectively analyzed and the stringent clauses of each standard are applied for the selection of pumps.

How to calculate the fire pump capacity?

Fire pumps capacity is calculated based on the class, nature & size of the risk. Industrial Fire consultants follow the latest editions of the following codes, standards data sheets for fire pump capacity calculation:

- IS 15105: deals with Design, Installation and Maintenance of Fixed Automatic Sprinkler Fire Extinguishing Systems — Code of Practice

- IS13039:External Hydrant Systems – Provision and Maintenance – Code of Practice

- IS 3844 : is the Code of Practice for Installation and Maintenance of Internal Fire Hydrants and Hose Reels on Premises

- IS 12469: Specification For Pumps For Fire Fighting System

- FMDS3-7 : FM Global Property Loss Prevention Data Sheet – Fire Protection Pumps

- FMDS 3-26: FM Global Property Loss Prevention Data Sheet – Fire Protection for Non-Storage Occupancies

- FMDS 8-9 : FM Global Property Loss Prevention Data Sheet – Storage of Class 1, 2, 3, 4 and plastic commodities

- NFP13 : Standard for the Installation of Sprinkler Systems

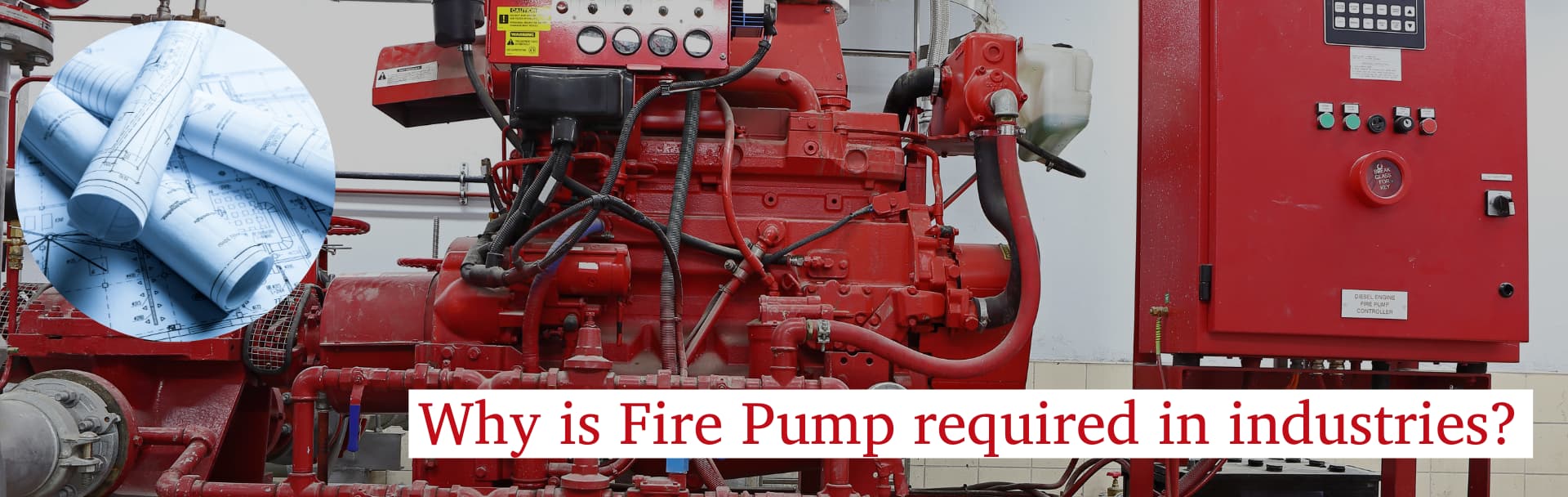

What are the main components of a fire pump system?

The components of the fire pump system are:

- Main Electric driven fire pump and accessories: Electrically operated pump with motor and accessories such as suction and discharge valves, suction strainer, non-return valve at discharge side, automatic air release valve, pressure gauges and circulation relief valve.

- Diesel driven fire pump and accessories: Diesel engine operated pump with accessories such as fuel tank with support legs, fuel system connections, suction and discharge valves, suction strainer, non-return valve at discharge side, automatic air release valve, pressure gauges and circulation relief valve.

- Electric driven jockey pump and accessories: Electrically operated jockey pump with motor and accessories such as suction and discharge valves, suction strainer, non-return valve at discharge side, automatic air release valve, pressure gauges and circulation relief valve.

- Fire pump control panel: Fire pump control panel for automatic starting of pumps in case of fire.

How does the fire pump start?

The fire pump starts as soon as the fire hydrant or sprinkler system pressure drops. The pressure drops as soon as one or more fire sprinklers are exposed to heat and release water. The opening of fire hoses and connections for firefighting could also be a reason for pressure drop.

What is the location and specifications of the fire pump house?

The fire safety consultants for industrial projects refer to IS 15301 for the installation of pumps and the location of the fire pump house. In case, the fire pump house is outside the building with a 6 meters clearance from neighbouring buildings.

If the pump house is inside the building, it should have 2 hours rated walls on all sides, separating it from the rest of the building.

The entrance door should have a 1-hour fire rating. It should be easily accessible from the outside with a ramp. If it is on the ground floor, it should be located on the peripheral side with access from the outside.

In case the pump house is in the basement, the pump house shall be provided with forced mechanical ventilation. Then the industrial fire safety consultant shall design the exhaust pipe of the diesel pump to extend outside and discharge at an appropriate height.