All industries will have a set of safety practices that are necessary for the firm. Specific measures are adopting which you can reduce destruction and increase the safety of the employees. When a sudden and unexpected fire outbreak occurs, Fire safety is one of the most important preventive measures to avoid anything disastrous to the life of the company. Industrial MEP consultants suggest some critical details related to fire safety, the causes of fire outbreaks, and how to prevent them.

To make it simpler to understand, by fire safety, what we mean is establishing a set of routine practices that will help to reduce the level of destruction in case a fire outbreak occurs. They should be planned at the onset of the business when you are constructing your industrial structure.

To make it simpler to understand, by fire safety, what we mean is establishing a set of routine practices that will help to reduce the level of destruction in case a fire outbreak occurs. They should be planned at the onset of the business when you are constructing your industrial structure. Any threat to fire safety is a hazard to the building. So, in addition to the fire safety measures, there should also be practical steps to avoid fire hazards in any fire safety implementation plan.

Any threat to fire safety is a hazard to the building. So, in addition to the fire safety measures, there should also be practical steps to avoid fire hazards in any fire safety implementation plan.

Before going into the elements that make the major components of a fire safety plan, let’s see what Industrial MEP consultants say about the causes of fires in industrial units.

Most often, fire outbreaks are due to the following factors.

- Combustible dust

- Work involving high temperatures

- Faulty Equipment and machinery

- Easily flammable liquids and gases

- Improperly supervised Electrical circuits

Fire safety implementation plan/fire protection system

With the help of Industrial electrical consultants, make a plan to ensure that the implementation of the safety measures is in place.

A hazard analysis is necessary.

At every critical point, make sure you have a system to analyze the hazards involved. If you detect even a minor risk that could cause a fire at any stage of production, take immediate measures to eliminate that particular factor. Regular hazard analysis should be undertaken.

Provide fire safety training

Employees need to know how to act in the time of a natural fire outbreak. Make them thoroughly aware of all the procedures and actions to be adopted in case of a fire actually breaking out.

Establish routine fire prevention and emergency procedures

The best way to equip your staff with fire procedures is to conduct mock fire drills. Making sure all your policies and safety measures are followed to the dot is necessary.

- Seamless evacuation of the building takes place.

- Install fire alarm systems at significant points.

- Get all the essential documents and files backed up in a safe place away from the main office.

Inspect regularly and maintain your equipment

Most of your equipment and machinery run 24 hrs a day. This is likely to cause wear and tear in the long run. One of the major causes of a fire explosion is non-maintenance of equipment. Regular inspections will help to identify maintenance issues and will mainly decrease the chances of risks. Test all your fire safety systems too frequently.

The ultimate checklist in a fire safety plan structure

- Important contact information

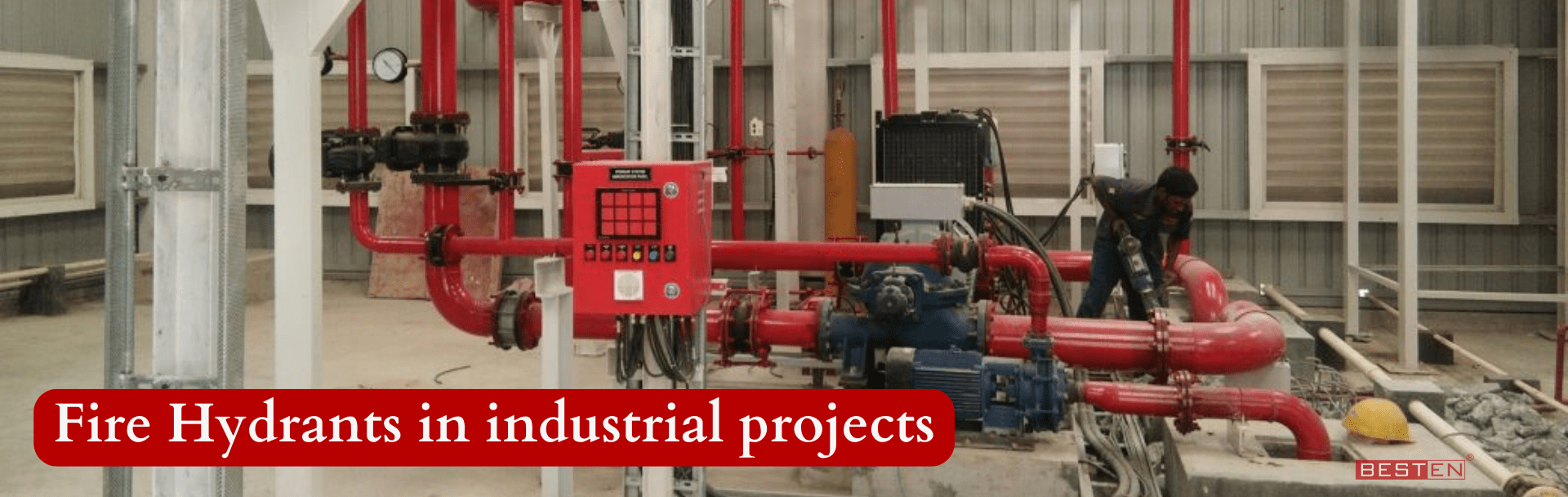

- List and location of Utility services (shut-off valves for water, gas, electric, fire extinguishers

- Layout, drawing, as well as site plan of the entire building

- Fire evacuation passage

- Up to date Maintenance schedules for all life safety systems

- Employee training and fire drill procedure

- Proper signages

Each industry differs in functionality, so implement your fire safety program and preventive measure accordingly by consulting the best Industrial MEP consultants.